LISA

(2019 – 2022)

LISA

(2019 – 2022)

LISA, standing for “LIthium sulphur for SAfe road electrification”, a 43-months research and development project, has been granted 7.9M€ by the European Union’s Horizon 2020 research and innovation program . The main goal of LISA is to develop an innovative Lithium chemistry with hybrid solid state electrolytes (SSEs) validated according to UN38.3 and EUCAR standards and ready for integration in automotive battery packs. The project directly builds on the results of the ALISE project (http://www.aliseproject.com) in which more than hundred pouch cells (290 Wh/kg, 240 Wh/L, 12.5 Ah) have been produced, and a first module for PHEV has been built containing 82 Lithium Sulphur cells. LISA aims to reach new performance levels of 450 Wh/kg and 700 Wh/L at costs < 70 € k/Wh at cell level positioning LiS technology in-line with EU SET Plan Action 7 targets on batteries for e-mobility. Moreover, with Renault and VDL Group on-board, prominent European OEMs for BEVs and e-bus, the technology will not only be developed and evaluated for light duty vehicles (LDVs), but also for medium duty transport applications (i.e. e-bus) with the main focus on fully electric drivetrains, i.e. BEVs.

The LISA consortium covers the full battery value chain for electromobility and includes raw material suppliers, component manufacturers, cell manufacturers, integrators, OEMs and a recycling company. The consortium has a balanced profile of 2 universities (Cranfield University, Technische Universität Dresden), 3 RTOs (Leitat, Fraunhofer IWS, CIC Energigune), 4 SMEs (OXIS Energy, Pulsedeon, Accurec, Optimat) and 4 large enterprises (Varta Micro Battery, Arkema, VDL, Renault), and includes the only European LiS cell manufacturer with commercially operating production plant (OXIS Energy). In LISA, Accurec will develop and demonstrate an efficient Li-S battery recycling process in respect of energy consumption, cost and recycling efficiency. To achieve the target, key technologies including low-temperature (e.g. cryogenic) pre-treatment, mechanical separation and hydrometallurgical treatment for lithium recovery are proposed and will be validated. Additionally, Accurec will support the environmental and economical assessment for the Li-S technology.

More details in project website: https://www.lisaproject.eu

NAIMA

(2019 – 2022)

NAIMA: New Na-ion cells to accelerate the European Energy Transition

The European project NAIMA aims to develop a new generation of high-competitive and safe Na-ion cells for the current and future energy storage technologies, supported by the key actors of the European Battery value chain

The new EU-funded project NAIMA “Na Ion materials as essential components to manufacture robust battery cells for non-automotive applications” was kickstarted in December 2019 in Amiens (France). This project was awarded a Horizon2020 programme grant of almost 8 M€ by the European Commission. The duration of the project will be 36 months.

The NAIMA project will demonstrate that two new generations of highly-competitive and safe Na-ion cells developed and tested during the project are some of the most robust and cost-effective alternatives to unseat current and future Li-based technologies in dedicated storage applications, nowadays controlled by Asian industry. The Na-ion disruptive technology is already supported by a solid European Battery value chain (industry partners of the consortium) through their solid commitment of substantial investments in the manufacturing of all components of a battery, preserving the ownership and industry strength around European countries.

The project consortium is composed of 15 partners from 8 European countries, and is led by the French company TIAMAT, which is specialized in the design, development and manufacture of sodium ion battery cells targeting fast charging, high discharge current applications in mobility and stationary storage sectors.

Accurec participates the project as a partner and is responsible to develop a sustainable and cost efficient recycling process for Na-Ion batteries.

For more information, please visit project website: https:www.naimaproject.eu/

ECO2LIB

(2020 – 2023)

The new EU-funded project ECO2LIB “Ecologically and Economically viable Production and Recycling of Lithium-Ion Batteries” launched in January 2020.

The ECO2LIB project is successor of Sintbat project, which managed to develop a cheap and energy efficient, maintenance free, lithium-ion based energy storage system. The ECO2LIB project adds to the successes of the Sintbat project, shifting focus to a new key performance improvement (KPI), the cycle related costs per energy: €/kWh/cycle. It very well reflects the real need of the customers if a minimum volumetric energy density is added. An extended LCA, cradle-to-grave will also be setup to judge the environmental impact of the different options and to choose the best. In fact, the ECO2LIB acronym was created to underscore the ecological and economical importance of the project.

ECO2LIB brings together a strong and complementary consortium, including 10 partners from 6 European countries. The project is led by VARTA MICROBATTERY Germany, and completed by international experienced scientific institutes and OEM`s.

Within the project, ACCUREC will lead the work package for recycling and the investigation of an innovative recycling route, with higher material efficiency and cost effectiveness.

For more information, please visit project website: https://www.eco2lib.eu/

LIBERTY

(2021 – 2024)

The EU-funded project LIBERTY “Lightweight Battery System For Extended Range at Improved Safety” launched in January 2021.

LIBERTY’s overall target is upgrading EV battery performance, safety and lifetime from a lifecycle and sustainability point of view. The key objectives of LIBERTY are to achieve a range of at least 500 km on a fully charged battery pack, halved charging times, an ultimate safe battery system, a long battery lifetime of over 300,000 km for first life, the ability to reuse the battery pack for second life applications and sustainability over the battery pack’s entire life cycle.

The innovations within LIBERTY lead to a compact high-performance battery pack with advanced diagnostic and control features and functionalities. In terms of consumer’s values, it brings extended range, short charging times, long distance travel capability, safety, reliability, user confidence and affordability. Led by Ikerlan S. COOP, LIBERTY consortium is composed of international experienced scientific institutes and industrial companies, including 16 partners from 7 European countries.

Within the project, ACCUREC will lead the work package for recyclability study of new battery pack for electric vehicle, as well as lithium recovery in battery recycling process.

For more information, please visit project website: https://www.libertyproject.eu

LOLABAT

(2021 – 2024)

Having started in January 2021, the Horizon 2020 project LOLABAT „LOng LAsting BATtery System“ funded by the European Union has been developing rechargeable nickel-zinc batteries (RNZB), which show enormous potential for the European martket, especially for stationary energy applications. The battery system is characterised by a high energy or power density, the absence of critical and toxic ingredients while keeping production costs low. With 17 partners from 7 European countries, the scientifically competent and economically oriented consortium covers the entire value chain from raw material to production to end-of-life and allows a detailed analysis of second use and recycling strategies.

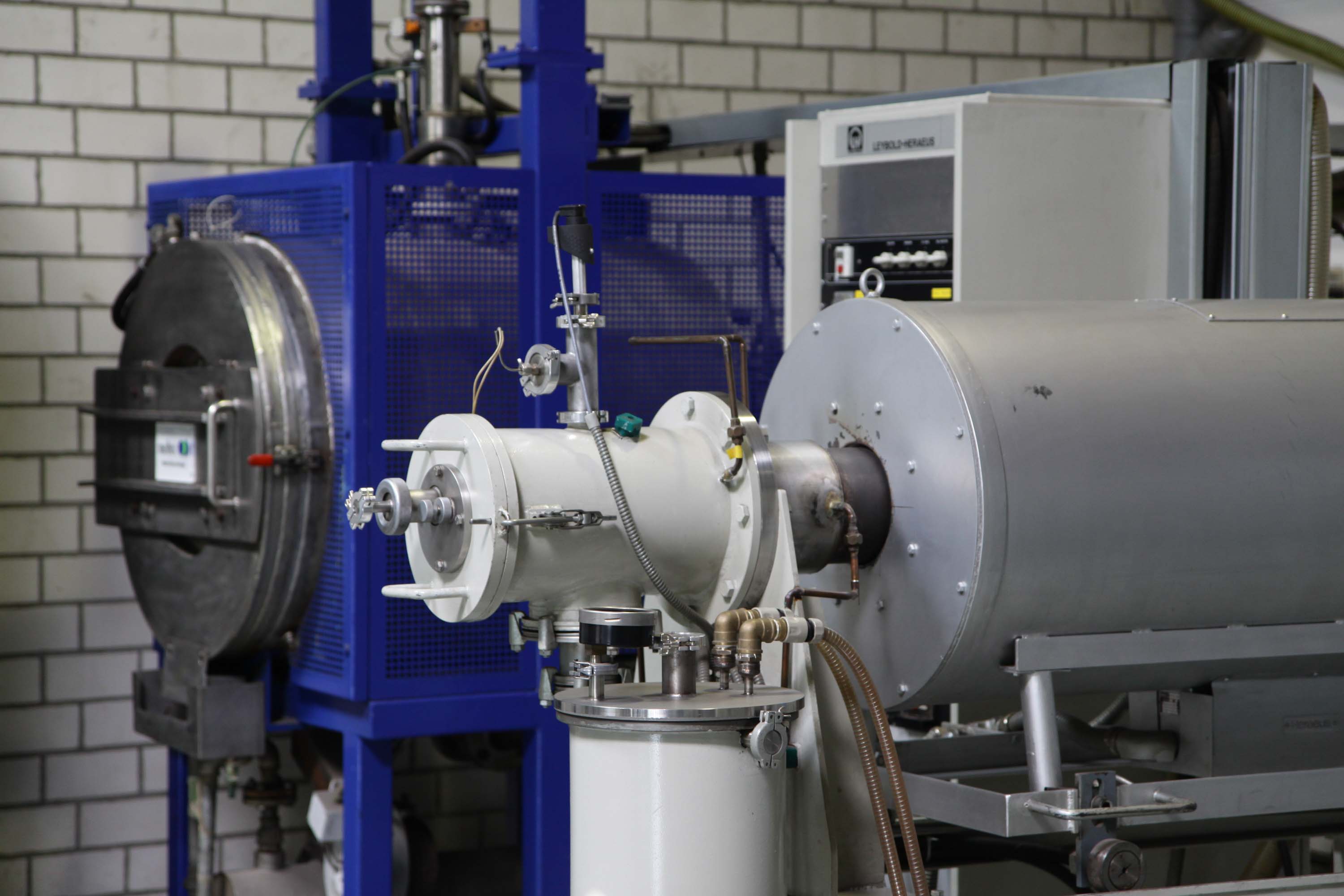

By focusing on the ecological consideration of the entire life cycle, the investigation of possible recycling technologies led by Accurec has a key position in the project. The work, which will begin next month, will compare, among other things, safe wet crushing of the batteries with consecutive hydrometallurgical treatment of the active masses to the best available technique of vacuum distillation developed and operated industrially by Accurec. For the evaluation of the different processes, the revision of the European Battery Directive will also be taken into account.

For more information, please visit the project website: https://cordis.europa.eu/project/id/963576/de

EARLI PROCESS

EARLI is a new project led by ACCUREC to install an economical and innovative process for recovering lithium from spent electromobile Li-ion batteries. The project, which is funded by the German Federal Ministry of Economics and Climate Protection, has a total budget of over 5 million euros.

While battery metals such as nickel or cobalt can already be recovered in higher yields, this is not yet the case for lithium due to the complex technical effort involved. But the research effort is getting a boost from the EU: European legislation will make the recovery of lithium mandatory from 2026 with its novel battery regulation. Accurec, Evonik, IME and Öko-Institut aim to install an industrial scaled process with thermochemical treatment and electrochemical separation to gain lithium as a high purity lithium hydroxide monohydrate.

“Through the EarLi project, and especially with Evonik as a partner, we want to significantly shorten the lithium cycle and efficiently close it for battery applications,” says ACCUREC Managing Partner Reiner Sojka.

(funding code: 16BZF305)

RHINOCEROS

(2022 – 2026)

The EU-funded project RHINOCEROS “Batteries reuse and direct production of high performances cathodic and anodic materials and other raw materials from batteries recycling using low cost and environmentally friendly technologies” will be launched in June 2022.

Rhinoceros will develop, improve, and demonstrate, in an industrially relevant environment, an economically and environmentally viable route for re-using, re-purposing, re-conditioning, and recycling of EoL EV and stationary batteries. Rhinoceros will first develop a smart sorting and dismantling system enabling the automated classification and dismantling of LIBs and the reassembly of still working modules in new repurposed batteries for second life applications such as batteries for energy storage systems. When direct reuse and repurpose of batteries is not possible, a circular recycling route of all the materials present in LIBs (e.g., metals, graphite, fluorinated compounds and polymers, active materials) will be followed to close the materials loop. This route is based on a set of cost efficient, flexible, and environmentally friendly routes targeting the pre-treatment, refining and the recovery of materials. Through product qualification by industrial end-users, Rhinoceros will demonstrate the direct production of high performances cathodic and anodic materials and other raw materials at competitive costs from battery recycling. The achievements will bring Europe to an increased independence level from foreigner manufacturers and raw materials suppliers.

Within the project, ACCUREC will lead the task for lithium-ion battery pretreatment and deliver high quality black mass to partner, simultaneously, recover the electrolyte and fluoride compounds in lithium-ion batteries. The project is led by Fundacion Tecnalia Research & Innovation and the consortium is composed of 16 international experienced scientific institutes and industrial companies from 9 European countries.

SUSTAIN

(2022 – 2025)

“Damage and condition analysis of defective high-voltage batteries” Acronym: SUSTAIN funded by the BMWK started in July 2022.

A meaningful and reliable condition assessment of lithium-ion batteries is necessary in order to avoid unnecessary recycling of old batteries in electric cars and to ensure safety in dismantling and recycling processes. With the expertise of three industrial partners and three technical colleges, a special diagnostic device will be developed over the next 3 years, which will enable both a risk assessment and provide information about potential further use. Recycling companies such as ACCUREC are targeted as the main branch of application, which can benefit from this analysis at customers or in their own company. This results in more safety and adapted storage and transport as well as it will conserve recycling capacity.