Europe`s first Lithium Recycling Plant

– Major Step for Raw Material Turnaround-

Press Release: December 9th, 2022

ACCUREC-Recycling is one of Europe’s leading companies for the recycling of rechargeable batteries. In early 2023, ACCUREC will now expand its process technology to include a recovery plant for lithium from rechargeable devices and electromobility at its Krefeld site. The plant, with a planned initial throughput of 4,000 tons of spent batteries, will be the first in Europe to reach an industrial scale.

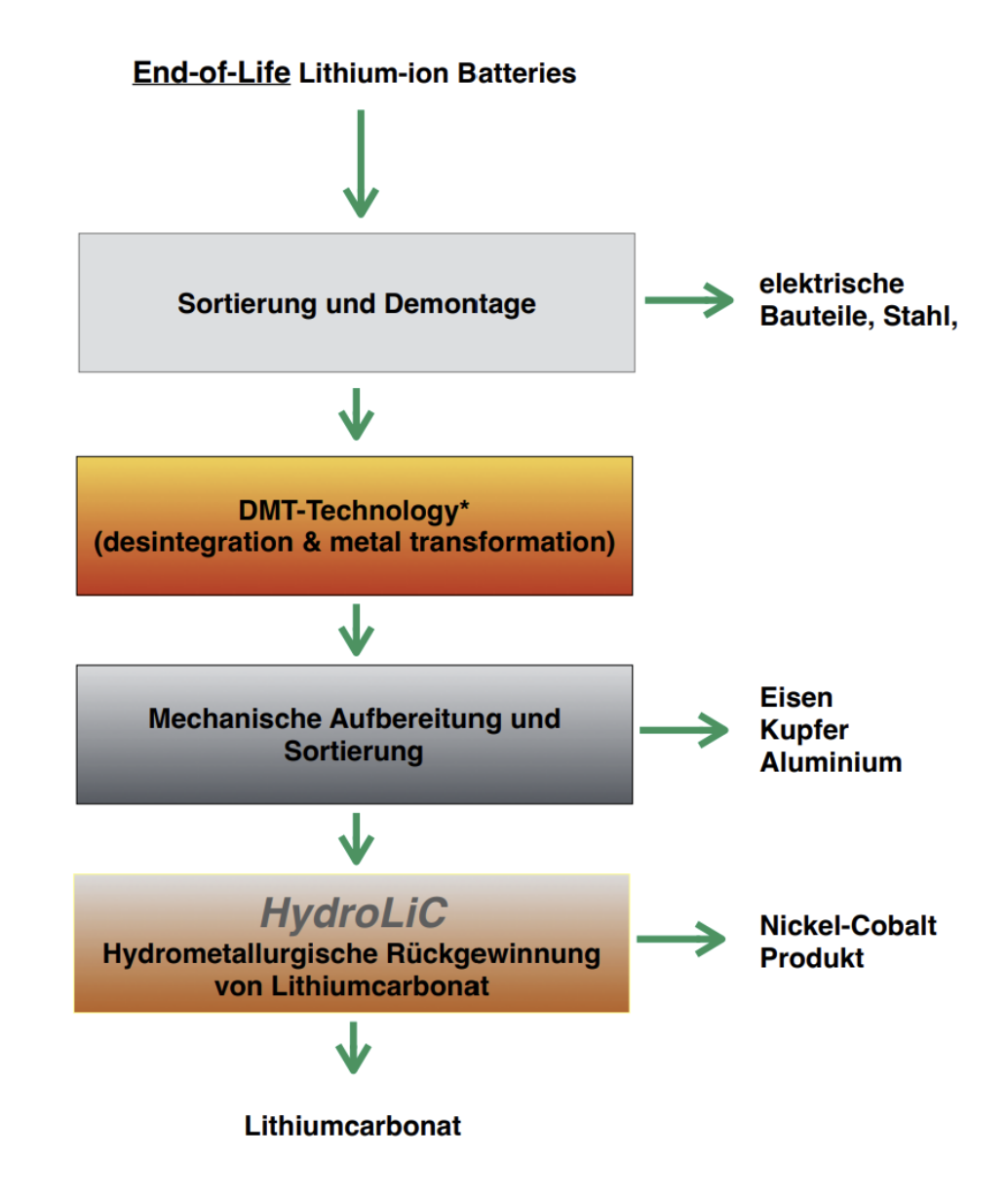

For about 8 years, Accurec has been dedicated to the challenges of spent Li-ion batteries and has already invested more than €20 million. Based on several research and implementation projects in cooperation with universities and equipment manufacturers, it will now be possible to recover the resource-critical lithium with about 99% purity as carbonate from the Li-ion batteries in electric vehicles, electronic devices, e-scooters and e-bikes through the in-house developed HydroLiC process (Hydrometallurgical LithiumCarbonate Recovery, Fig. 1). “This completely new technology will be a major step towards a raw material- and energy-efficient recovery of the precious light metal lithium from the previously poorly usable black mass. We are now in a position to meet the growing demand for lithium not only from primary raw material sources. With a fraction of the energy input compared to primary extraction, we succeed in recycling and improve the CO2 balance elementarily,” commented Dr. Reiner Sojka, Managing Partner of ACCUREC, on the new development. With the amendment of the EU battery regulation, there will be an additional recycling quota that requires a recovery of min. 35% for battery lithium by 2026. With its HydroLiC technology, ACCUREC will not only be able to reliably meet the planned quotas by the time it goes into operation, but will also be able to exceed them.

The demand for lithium will accelerate enormously in the coming years. For e-mobility alone, experts from the Ökoinstitut1, based on the German government’s climate protection plan, expect an increase from around 750,000 e-vehicles2 today to 7-10 million German e-vehicles in 2030. They will thus consume up to 50,000 tons of lithium alone by 2030. Depending on the demand scenario, global demand for lithium will even increase to about 500,000 tons of lithium by 2030, and about 90% of this will be due to electromobile applications. According to the German Raw Materials Agency (DERA, 20223 ), lithium production will therefore have to be expanded by a factor of 4-7 in the coming years in order to meet the forecast demand. The fact that demand is picking up can be observed in the recent sharp rise in prices. According to a recent study by the German Raw Materials Agency (DERA), the price of a lithium concentrate in 2021 has increased sixfold in a 9-month period4.

- https://www.erneuerbar-mobil.de/sites/default/files/2020-09/Strategiepapier-Mercator-Recycling- Batterien.pdf

- https://de.statista.com (November, 11th. 2022)

- https://www.bgr.bund.de/DE/Gemeinsames/Oeffentlichkeitsarbeit/Pressemitteilungen/BGR/DERA/dera- bgr-2022-06-24_pm_dera-stellt-ergebnisse-der-rohstoffrisikobewertung-lithium-vor.html?nn=1542388

- https://www.deutsche-rohstoffagentur.de/DE/Gemeinsames/Produkte/Downloads/Rohstoff- Trends/rohstoff-trends_04-21.pdf?__blob=publicationFile

Fig.1: Process flow diagram, the *DMT technology is used to debind the functional metals bonded to the electrode foils and thus enable their separate separation to be further processed in the downstream steps with virtually no losses.

In order to actually achieve the required sustainability with the traffic turnaround, the huge lithium demand must increasingly be covered by recycling. It is therefore imperative that the development and expansion of capacities with state-of-the-art recycling technology progresses rapidly worldwide. “With our new lithium recovery plant, we are leading the way in the true raw material turnaround,” said Reiner Sojka. “Since no industrial technology has been available in Europe and the U.S. until now, we can now close the gap between primary recovery and rapidly growing Li demand economically and with decentrally operating modules.”

Background information: ACCUREC-Recycling GmbH, a medium-sized, technology-oriented company with sites in Mülheim/Ruhr and Krefeld, is an internationally active company in battery recycling, most recently with annual sales of around €20 million and 80 employees. Founded in 1995, it has developed innovative recycling processes for all common battery systems and implemented them on an industrial scale. Each year, ACCUREC recovers more than 5 million kg of critical and industrial raw materials from accumulators.

Contact:

- ACCUREC-Recycling GmbH, Bataverstr. 21, Krefeld, www.accurec.de, Managing Director: Dr. Reiner Sojka (Tel. +49-2151-652980)

- Kummer: Umweltkommunikation GmbH, Gebr. Grimmstr. 17, Rheinbreitbach, www.beate- kummer.de, Managing Director: Dr. Beate Kummer (Tel. +49-2224-9011480)